Current mileage: 27,927

Today’s maintenance:

- Drain and flush the cooling system

- Remove the cooling tubes and elbows, replace all o-rings

- Pull thermostat housing, replace o-ring

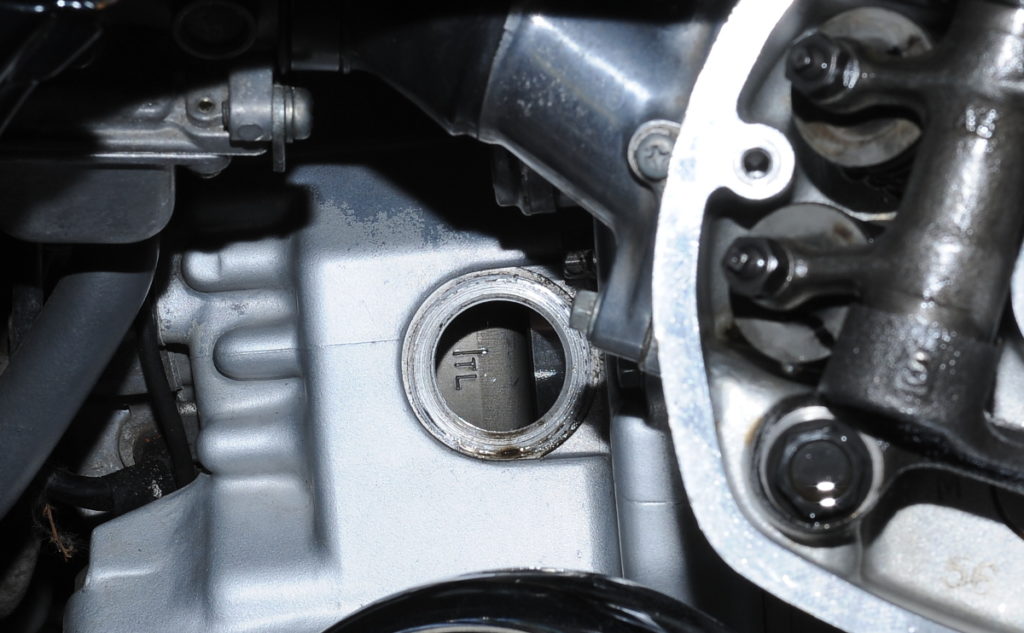

- Replace coolant sensor with NAPA EDH TS6045

- Test thermostat

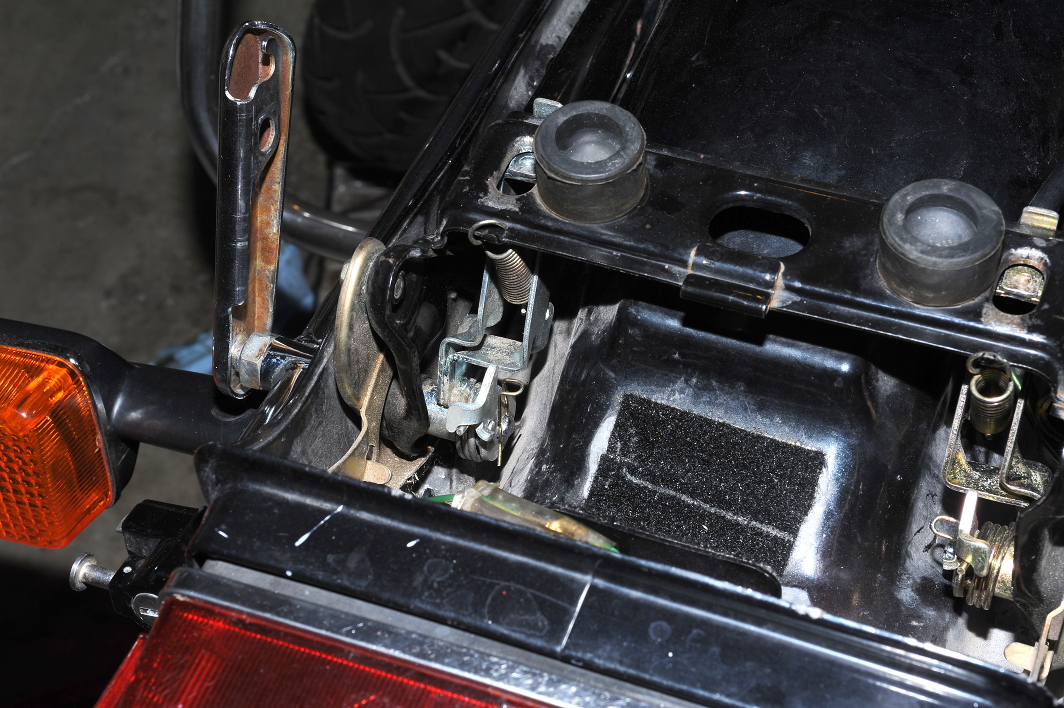

- Cleaned out crud from under thermostat housing (more on left cylinder, than on right, need to check cylinder valve cover seal).

- Filled cooling system with Prestone DexCool Extended Life coolant

- Changed oil: Honda Filter 154A1-413-505, Rotella T4 15W-40

- Cleaned up crud under thermostat as well as various cooling system parts (e.g. tubes, housing, hose clamps).

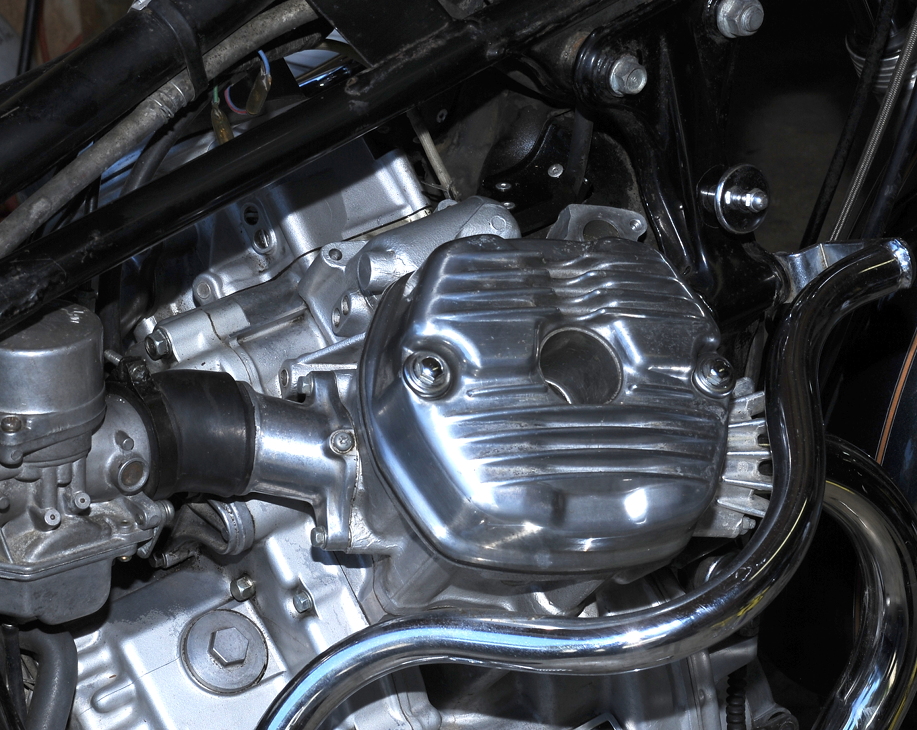

The internals of cooling system are very clean. The thermostat looked brand new. I tested it for proper operation before reinstalling it. I purchased a NAPA part to replace the thermostat, and while it would have fit, the NAPA thermostat (THM 535080) had a smaller diameter valve and didn’t look like it would pass as much coolant, so I returned it.

The radiator has a minor amount of scale buildup visible through the radiator cap, but it doesn’t yet need to be boiled clean. Will check again at the next coolant change.

Based on internet research, I bought a NAPA radiator hose (NBH 11644). Other owners reported that they could cut this up into the pieces needed to replace the Honda radiator hoses — which are no longer available. The hose diameter looked way too small, so I also returned this part. Perhaps they increased the hose diameters with the GL500? The good news is that the hoses I pulled off were in very good condition, pliable and no cracks, so they should be good for several more years.

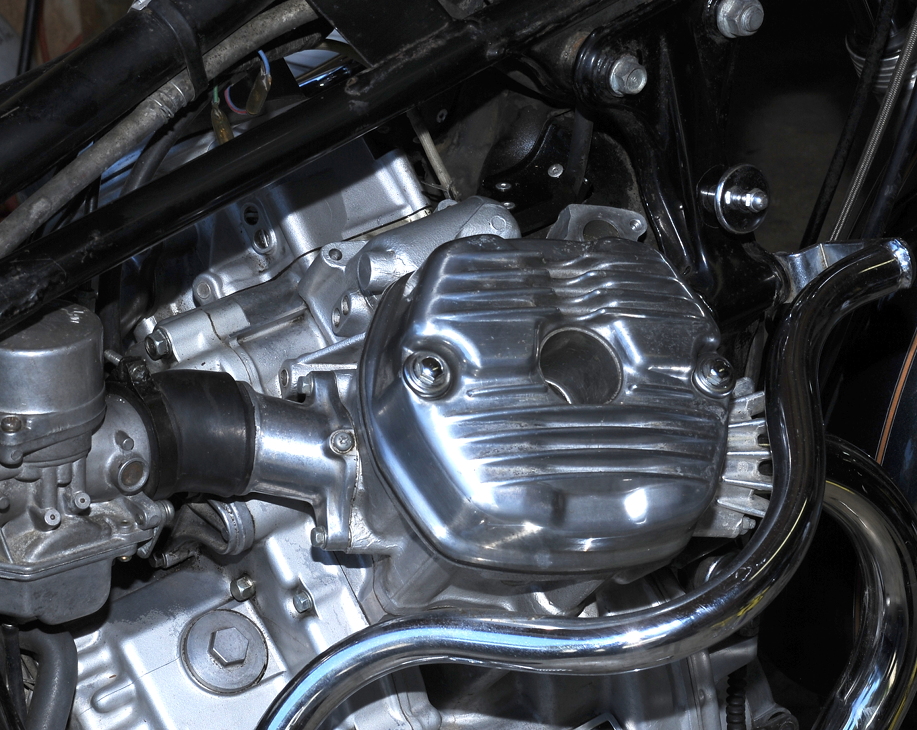

With the coils and thermostat housing removed the crud on the left cylinder was visible. It looks like there was a valve cover leak. Need to check that. Note how clean the cooling system inlet is on the far right, where the cooling tube elbow attaches.

As you can seen from the green coolant in the photo above, the bike had regular Prestone antifreeze in it. I flushed this all out with distilled water and replaced with Prestone DexCool Extended Life. This is less abrasive (non-silicate, better for water pump seals) and is aluminum safe.

TIP: The screws to drain the extra 0.4l of coolant from each cylinder are impossible to get to so I didn’t drain those. Instead, after flushing with distilled water and draining the radiator I just assumed that I had still 0.4l of water in the system, so I added 0.4l of undiluted coolant before filling with a 50/50 mix of coolant and distilled water.

This is before I reinstalled the thermostat and coils — all nice and clean. Now it will be easier to spot leaks.

The radiator is in good shape. You can see inside the thermostat housing. Very clean. That large o-ring in the thermostat housing was replaced. Both radiator hoses are in good shape, as are the four hose clamps, so they were cleaned up and reinstalled.

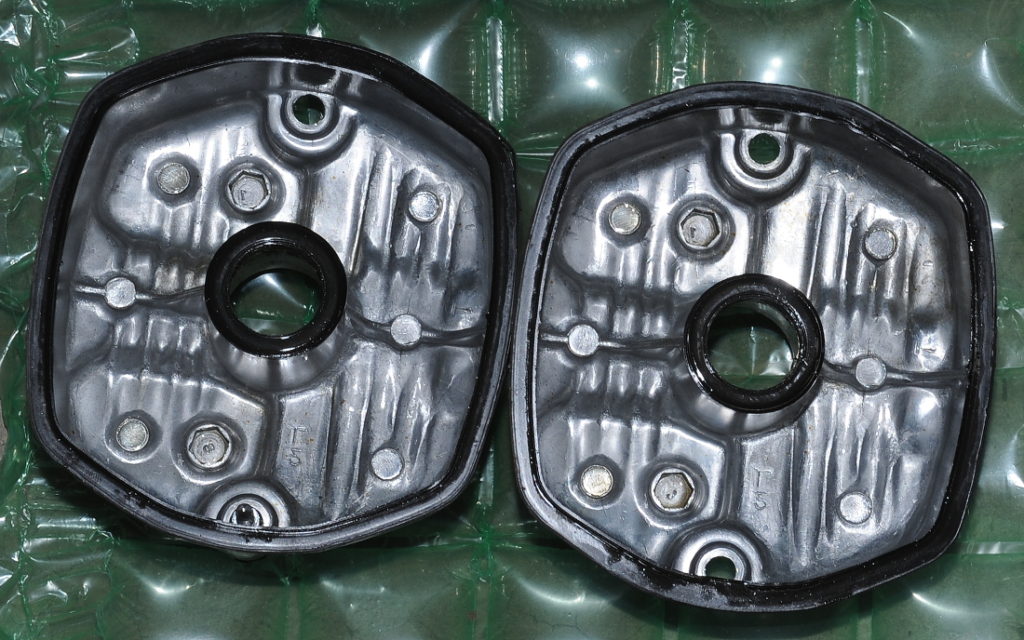

The cooling system o-rings definitely needed to be replaced. This is the lower-radiator tube end that goes into the back of the engine. I replaced this, plus the four o-rings on the short tubes that go from the thermostat housing to the cylinders, and the two o-rings that go between the cylinder and the tube elbows. I was able to purchase all of the parts at the local Honda dealer.

I didn’t pull the radiator fan to check for cracks, I’ll do that next time. From the front the fan and shroud looked to be in good condition. I did loosen and re-torque the fan bolt.