Mileage: 27,973

Today’s Maintenance:

- Replace all remaining valve cover rubber.

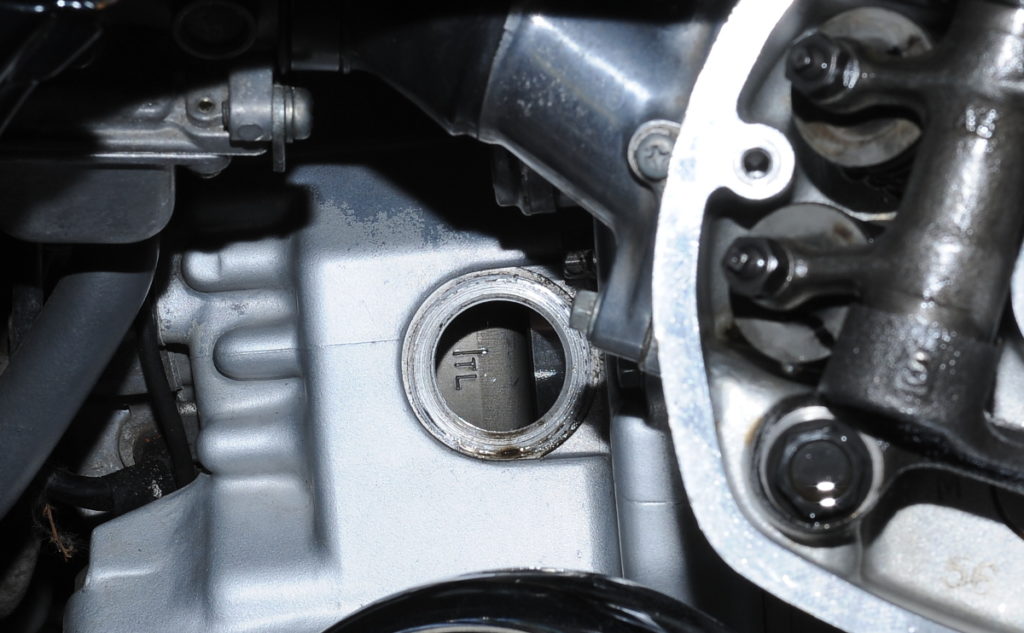

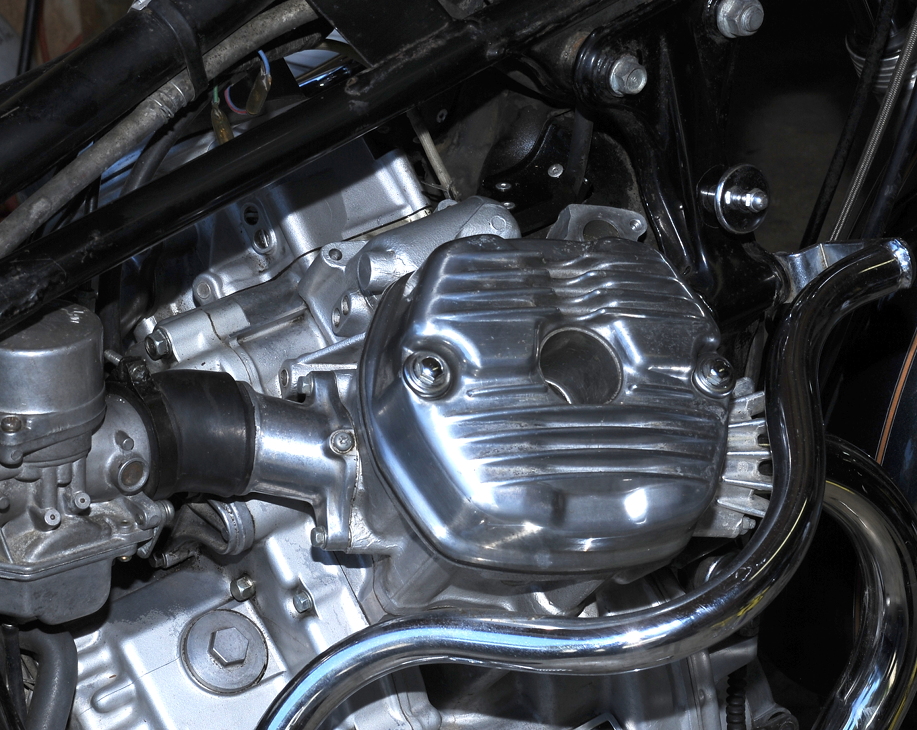

When I adjusted the valves a week or two ago I replaced the large outer valve cover gasket. Unfortunately I had neglected to purchase the smaller gasket that goes around the spark plug well. I reinstalled the old center gaskets and ended up with an oil leak that stopped after a couple of short rides.

The leak was a little puzzling at first because there didn’t seem to be any oil on the new valve cover gasket. That’s because the oil was leaking into the spark plug well when the engine was running and coming out a drain hole on the lower side of the cylinder case.

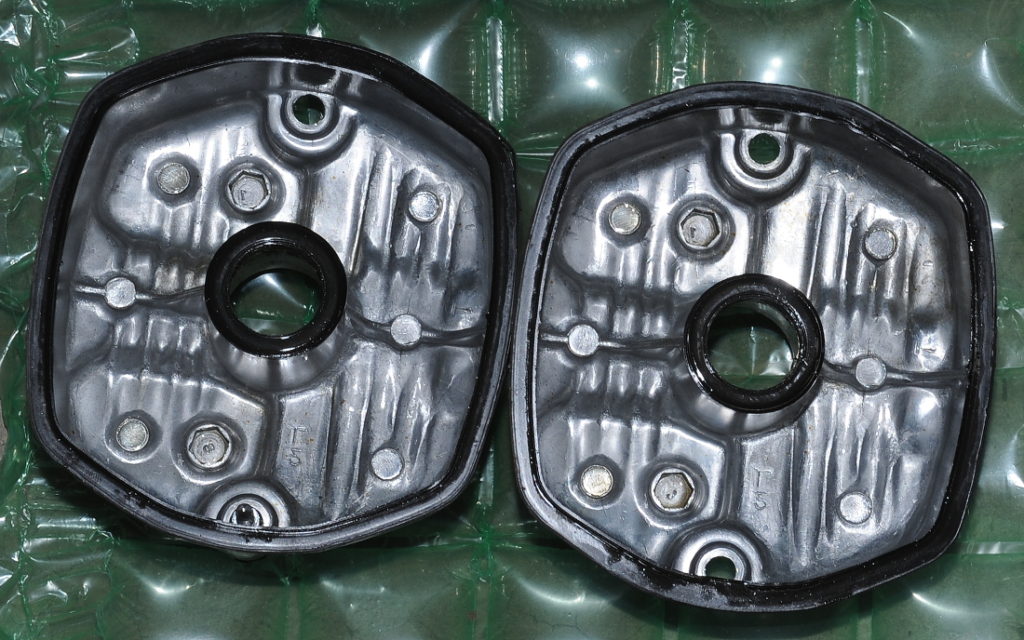

While pondering the leak I realized two things. One, the new gasket would be thicker and so the old, center gasket might not have as much pressure applied. Two, that the “rubber, settings” as they’re called in the parts fiche, were probably a bit flat too. These are the rubber seals that fit around the valve cover bolts and apply downward pressure to the cover. So new rubber was ordered and installed.

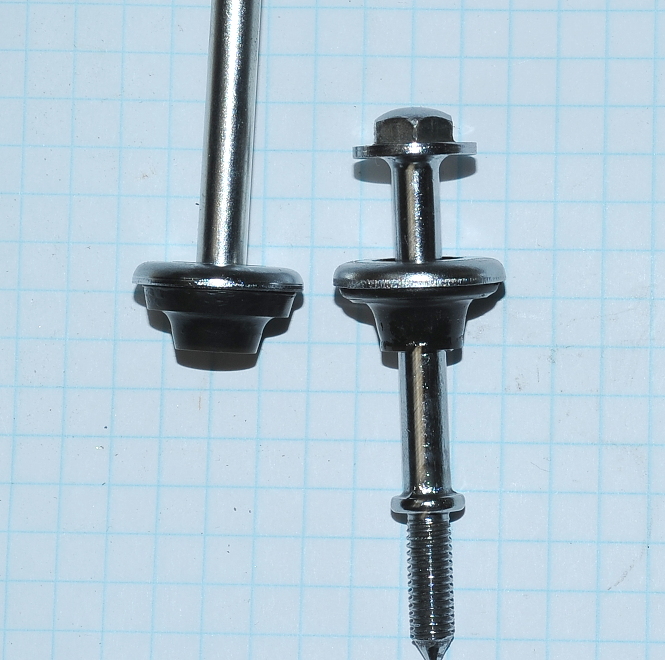

Below is a picture of a valve cover bolt with what I’ll call the hold-down seal. You can see how compressed the old rubber on the right is relative to the new rubber the left. I cut the old rubber off with a knife after separating the rubber part from the cap. The new parts have beveled rubber on the cap side and push on over the bolt’s shoulder without too much effort. With the new parts installed I could definitely tell there was a lot more pressure on the valve cover as I tightened the bolts down to the metal stops. Shouldn’t leak now.

As an aside, these parts are shared with Goldwings, so while I installed Honda OEM parts, there are non-OEM versions of this part available as well. In fact while four of these are used on the GL500, eight are used on Goldwings, so I found a lot of 8-packs available on eBay when I was searching for parts.